Experienced metrologists, High accuracy 3D Scanning systems and latest Software Technologies in our lab will help to solve your most demanding dimensional inspection issues, digitizing, and all other facets of manufacturing that have to do with 3D metrology.

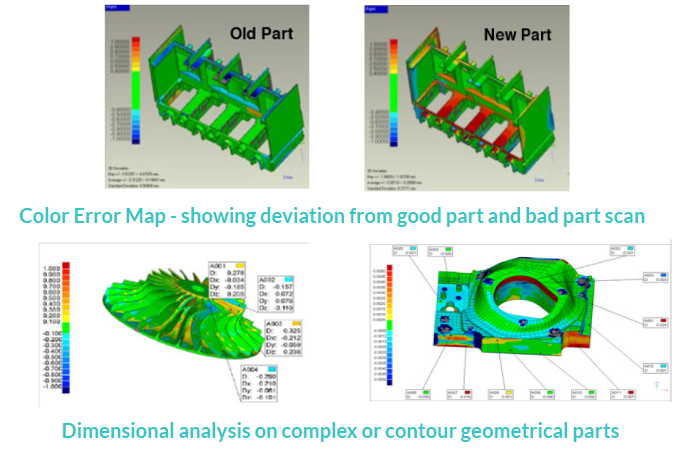

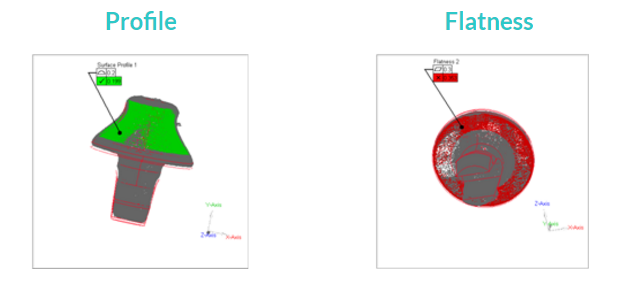

Through the scanning of a physical part, high accuracy 3D scan data is compared directly with the designer’s CAD nominal data to verify that the finished part or tooling conforms to the original design intent. Alternately, two sets of point cloud scan data can be compared with each other during the manufacturing process to assure parts stay in spec.

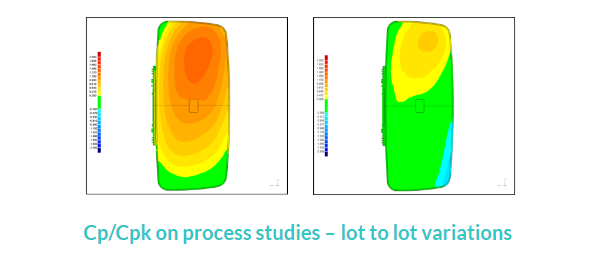

The result of this comparison process is delivered in the form of a “colour map deviation report,” in PDF or word format, which pictorially describes the differences between the scan data and the CAD data or good sample data.

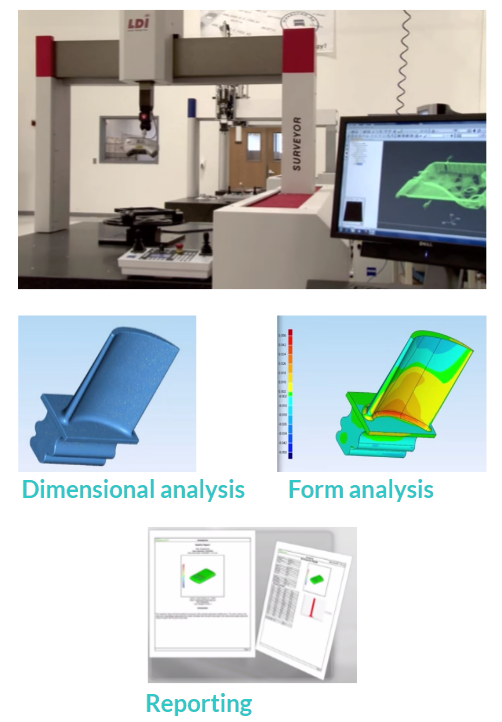

Be it Dimensional analysis or Form analysis, our Engineer will study and fully understand customer requirements before the job so as to provide a report tailored to each customer needs.

Typical 3D Inspection services include First article Inspection, 2D Functional Critical Dimension, GD&T Analysis, Cp/Cpk studies, Product / Tooling verification with CAD, Process Control studies, Failure Analysis, Trend Analysis, Multiple cavities studies, etc.

Speed up your part or tool qualification, send us your part for scanning, our Engineer will study the drawing data, fully understand the requirements before the job so as to provide a report tailored to each customer needs.

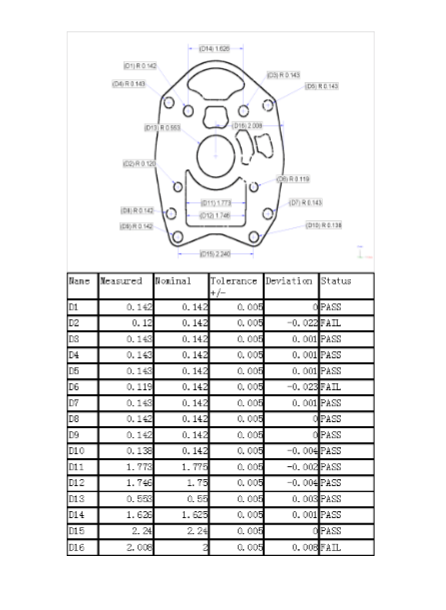

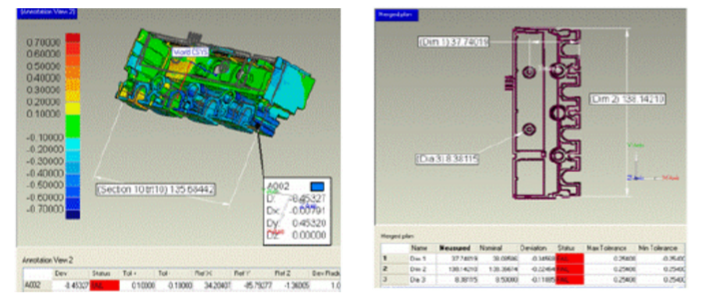

First Article Inspection – GD&T Analysis

Speed up your part or tool qualification, send us your part for scanning, our Engineer will study the drawing data, fully understand the requirements before the job so as to provide a report tailored to each customer needs.

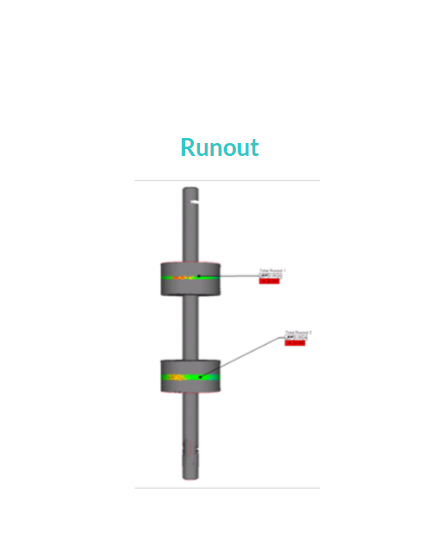

First Article Inspection – Product / Tooling verification with CAD

Speed up your part or tool qualification, send us your part for scanning, our Engineer will study the drawing data, fully understand the requirements before the job so as to provide a report tailored to each customer needs.

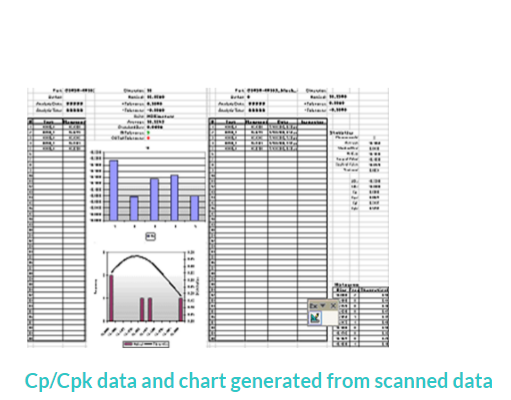

Cp/Cpk studies

Fast automated report generation from scanned data. For process capabilities and control studies, multi cavitites studies, trend analysis, lot to lot variations, predict tool wear, etc.

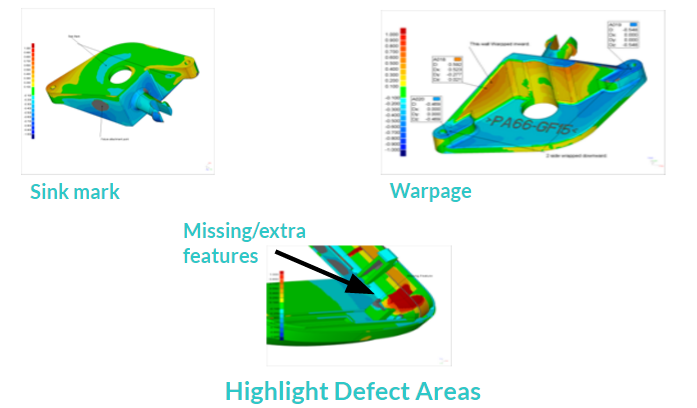

Failure Analysis

Speed up your failure analysis or investigations, send us your good part and bad part for scanning, the problem areas will be revealed through interactive graphical illustrations.